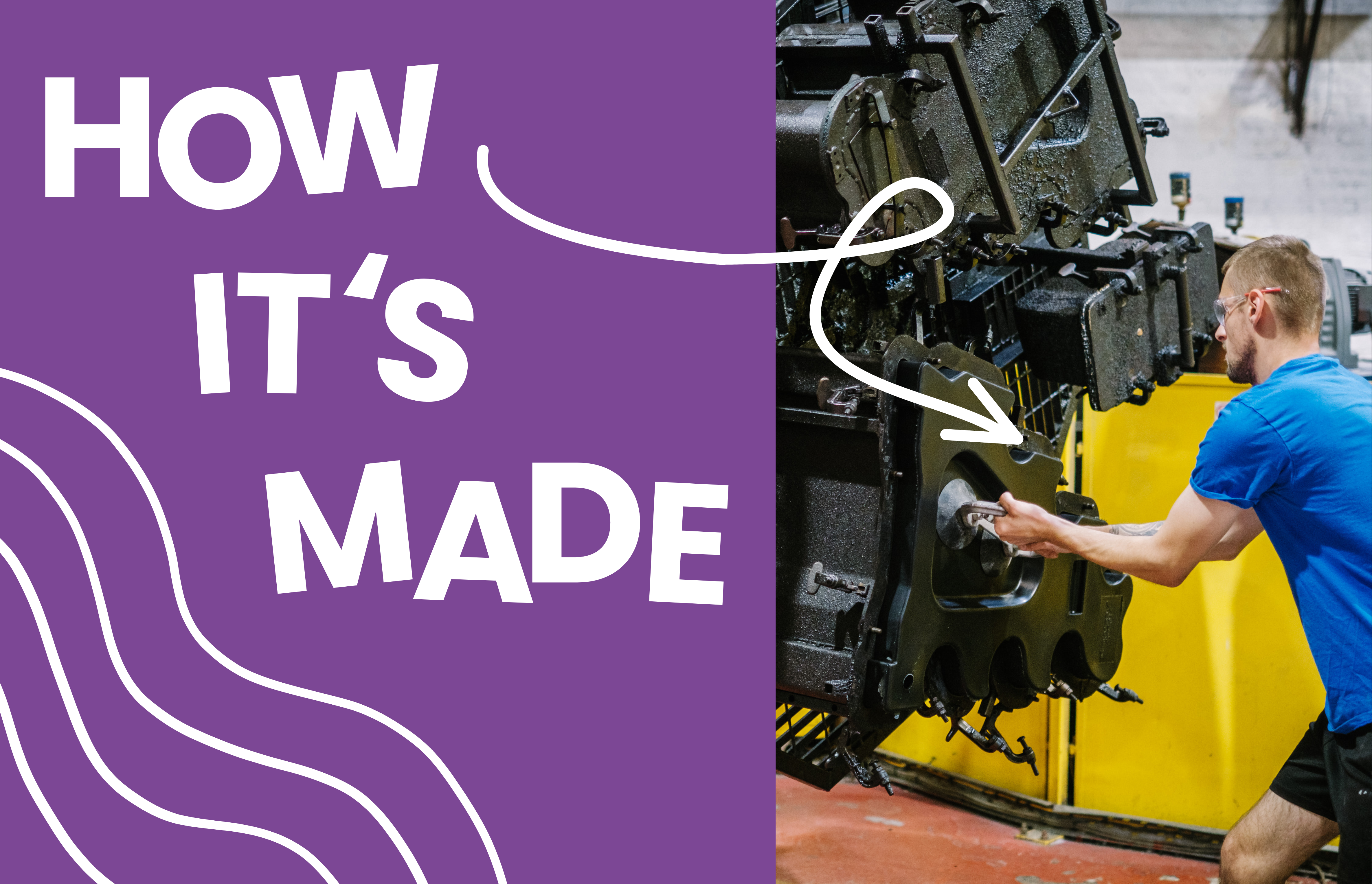

Take a sneak peek at our manufacturing process which takes place at Excelsior Ltd.’s factory in Bury. Rooted in tradition and innovation, ensuring that every product meets the highest standards of quality and performance.

Our Heritage

Classic Showjumps is a trading arm of Excelsior Ltd, a family-run business established in 1902. Over the years, we’ve evolved from horse-drawn coal carts to becoming one of Europe’s leading manufacturers of equestrian products. Our 44,000 sq. foot facility in Bury, Lancashire, houses a variety of roto moulding machines. This allows us to produce high-quality products for trade and retail.

The Roto Moulding Process

Our products are made using a technique called rotational moulding. Although it sounds complex, this process involves placing polyethylene powder into a mould, which is then heated in an oven while rotating on two axes. As the mould heats up, the powder melts and evenly coats the inside, creating a hollow, seamless product with consistent wall thickness. Once cooled, the product is removed from the mould, resulting in durable, long-lasting items.

What are the advantages of using this material?

Excelsior: Durability and versatility

Our products are made from premium UV-stabilised polyethylene. This ensures they can withstand harsh outdoor conditions, lasting a lifetime.

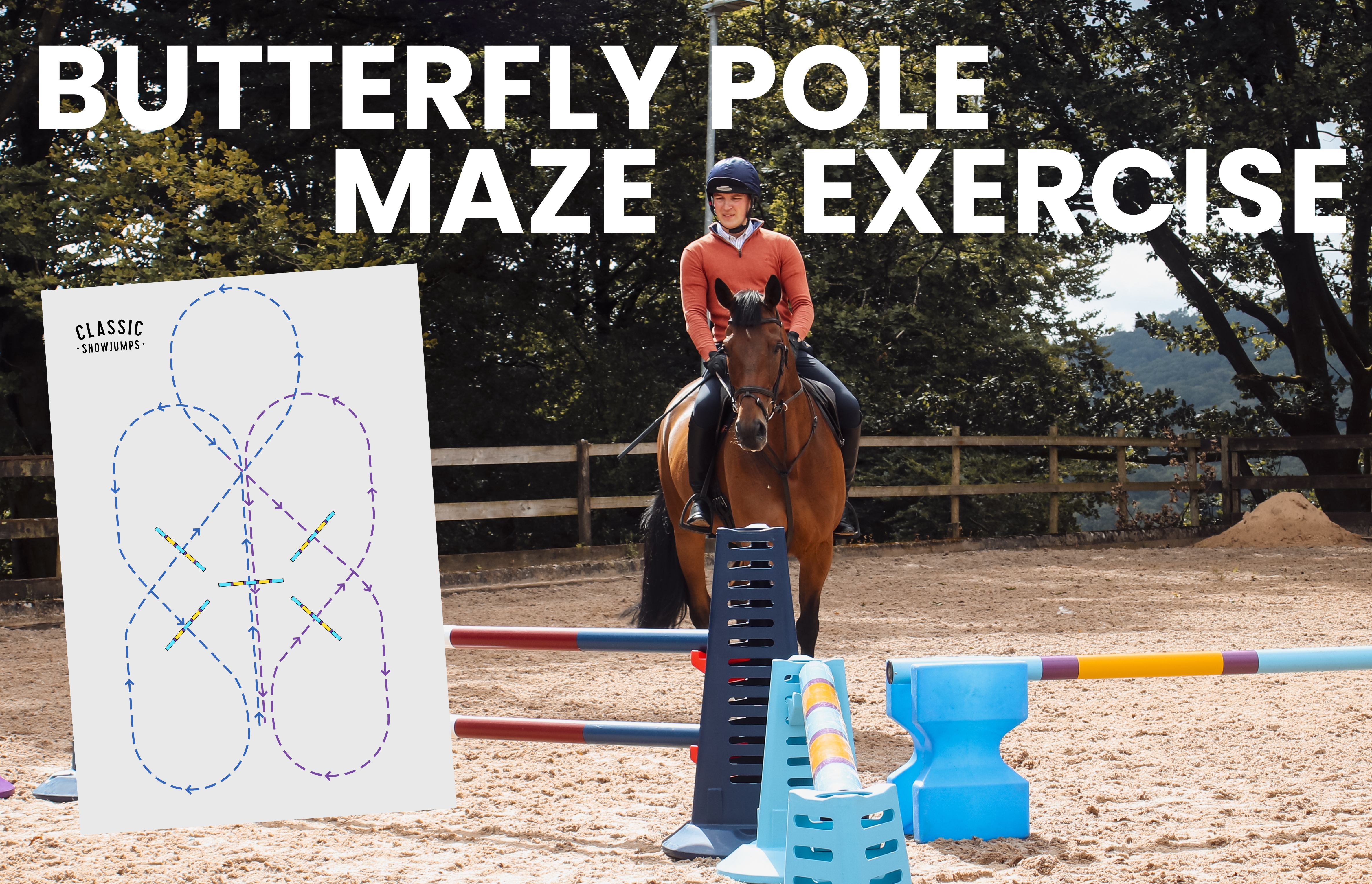

From show jumps to mounting blocks and feed bins, our range caters to the diverse needs of stable owners and riders giving you peace of mind with our delightful British weather!

Sustainability

Excelsior Ltd. have a strong commitment to reducing their environmental impact by recycling and reusing waste materials. Their products help reduce the carbon footprint by being locally manufactured and supplied.

What’s next?

Get ready for a series of interviews we have lined up with jockeys and equine professionals where we take a deep dive into their careers and learn all about their experiences.

Read all of our latest news Hier.